Our country is a country in the process of industrialization and modernization. In recent years, a number of industries are being focused and developed by the state: Processing technology, Electricity, Electronics – Telecommunications, Automation and new energy – Renewable energy. From there, we can see the appearance of modern industrial factories in all provinces in our country. Leading to an increasing demand for the production of electrical, electronic and industrial automation equipment. This also shows that adhesives for the electronics industry play a key role in the production process of creating finished products, reflecting the quality of the product indirectly.

Some types of HOT MELT ADHESIVE that HOA XUAN is providing to the electronics market:

1.Hotmelt glue for consumer electronics assembly:

Hot melt adhesive lines are used to assemble smartphones, tablets, wearable electronics, wireless speakers and other mobile electronic devices, etc.

Advantages of using HOT MELT ADHESIVE to assemble consumer electronics:

● Helps form quick bonds to increase production productivity.

● There are many methods used that allow engineers to be flexible when conducting assembly.

● Good gap-filling ability allows for greater tolerances in part design.

● Excellent moisture resistance.

● They have a long shelf life and do not require refrigeration or other environmental controls.

2. HOT MELT ADHESIVE used in assembling screens and battery cases

● Silicone hot melt adhesive has high moisture resistance and is used in bonding flexible materials to metal very effectively. Glue is sprayed onto the material to be glued using automatic or manual glue spraying equipment. Nozzle diameter can be as small as 0.5mm.

● PUR hot melt adhesive for structural bonding of portable electronic devices, very suitable for bonding metal, ink-coated glass and plastic, shock and impact resistant items. Besides, PUR hotmelt glue is widely used in electronics assembly for applications such as bonding screens to phone cases, and components…In addition, electronic device manufacturers are trying to trying to make their mobile devices more waterproof. Really thin duct tape has no ability to prevent water penetration. But hot melt adhesives can provide gap filling and help waterproof the assembly.

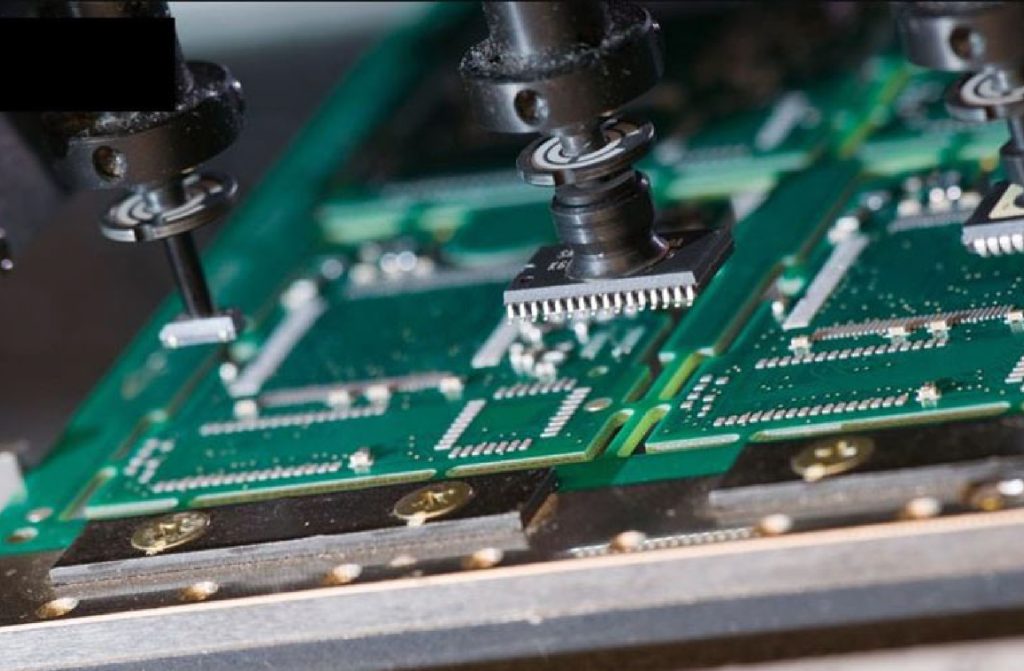

● Previously, the edges of the batteries would be folded over and sealed with single-sided tape. Now, battery manufacturers are using PUR hot melt adhesive to replace it. Additionally, PUR hot melt adhesive is also replacing double-sided tape to keep batteries in place inside mobile devices. Glue can be sprayed in every angle by robots or automatic systems to help save costs in time, labor, and increase productivity.

● UV hot melt adhesive is used to attach LCD, OLED or touch screens to electronic devices such as mobile phones, tablets and other electronic screens. UV hot melt adhesive, specifically designed for applications requiring high transparency, provides clarity, low shrinkage and high adhesion, ensuring long-term performance of the display. Manufacturers can produce display devices with outstanding aesthetics and durability.