In the wood production and processing industry, wood glue is one of the key materials that determines the quality of the final product. Wood glue is a highly adhesive compound. The product is specialized for gluing wood and wooden materials in the carpentry and furniture manufacturing industries. With good adhesion, it can be used to replace drilling and nailing methods.

At HUACHUN, we provide a variety of wood glue lines for many different applications, including:

1. Wood glue

This is a line of glue that is very commonly used in the interior and exterior wood furniture manufacturing industry. Milk glue is used to glue and assemble wood, horizontal joints, and vertical finger-joint joints and is suitable for semi-automatic or automatic machines

2. Hotmelt glue (EVA-based hot melt glue): applications for veneering, edge gluing, etc.

a. Wood edge gluing: To enhance aesthetics, modern furniture products need to be designed with sophisticated edges. Because of the above practical needs, the adhesive industry has created optimal solutions. to process curves and edges of wooden panels. These are hotmelt glues for edge stitching, also known as edge glue.

Hot melt edge banding offers many benefits for edge banding applications in the furniture industry:

● Excellent adhesion.

● High heat resistance.

● High humidity resistance helps increase resistance to harsh weather conditions.

● The glue lines are even and the glue lines are beautiful

b. Pasting veneer panels:

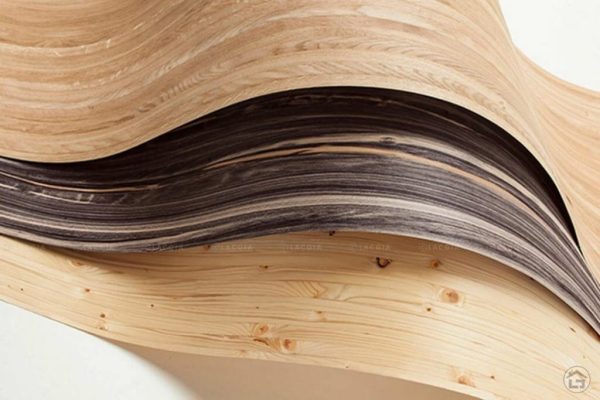

Veneer panels are a material with a thin and brittle surface used as lining panels on pressed wood and plywood surfaces, with eye-catching and diverse natural wood grain patterns. Unlike natural wood, veneer panels are cheap and given the huge demand in the wood industry, veneer panels are being widely used in the construction of furniture such as tables, chairs, cabinets…

However, in large sized products, small veneer panels will not be able to accommodate. Therefore, the need to join veneer sheets together to create a large veneer sheet with virtually no change in quality and aesthetics will require EVA hot melt adhesive products to meet this requirement.

The nature of this glue is that EVA glue particles are produced in the form of fibers with high adhesive strength and breaking strength. Then use a specialized machine to sew the two veneer panels together. Then, use heat to melt the glue and press the two veneer surfaces together.

3. PUR hot melt adhesive

PUR hotmelt adhesive is used in joining panels of materials such as industrial wood boards and plastic wood onto thin surface material panels such as thin PVC film, Acrylic or Laminate.

Advantages of PUR thermal adhesive in the furniture industry:

● Used extensively in humid or hot environments, can withstand heat effects and is ideal for hard materials.

● Sun resistant to chemical effects on the surface of the material, helping to increase moisture resistance and fire resistance better than conventional wood glues.

● Does not create glue edges, ensuring good coverage when mass-coating the surface of the material.

● The extremely high durability and flexibility of PUR hotmelt glue thanks to the formation of stronger bonds when exposed to air humidity.

● PUR hot melt adhesives are low in volatile organic compounds (VOCs) compared to traditional hot melt adhesives so they reduce the need for drying or cooling time.